AAC Blocks (Autoclaved Aerated Concrete) is a certified green building material. These precast concrete blocks are extremely lightweight and widely used for internal and external construction

80% of the volume of an AAC block is air. The blocks are easy to install, nail, drill and cut for pipes and conduits. We manufacture the AAC blocks in a variety of sizes. The raw materials we use to manufacture these blocks are cement, sand, fly ash, gypsum, lime and water.

SIZES AVAILABLE

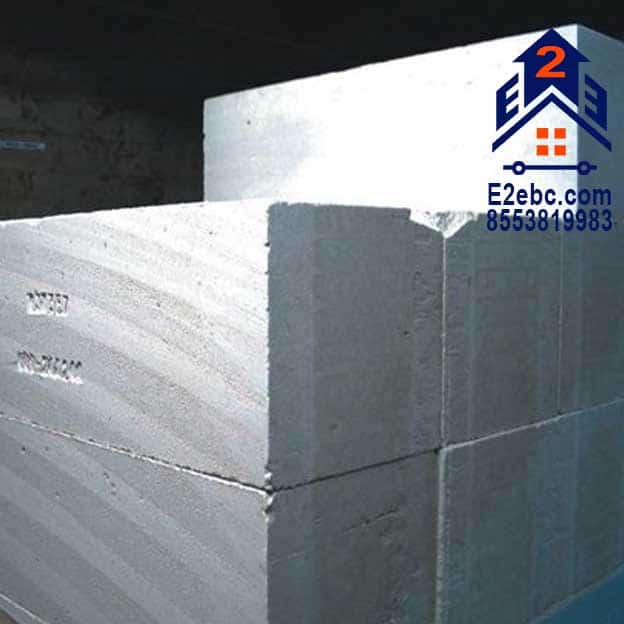

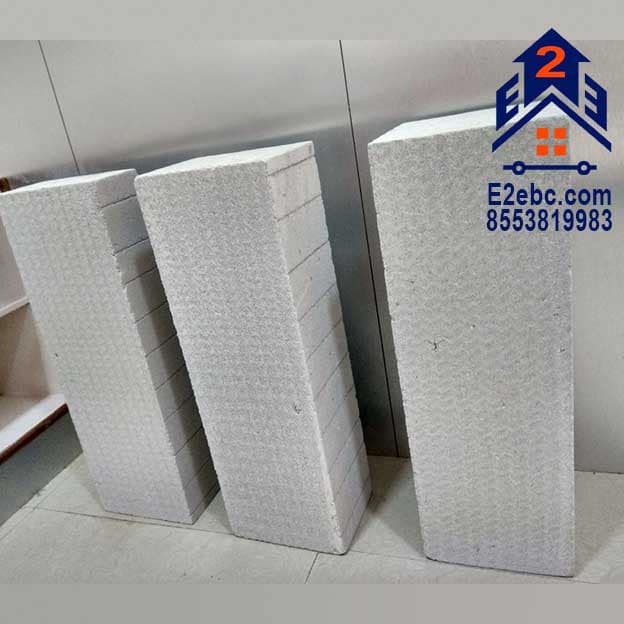

PRODUCT IMAGES

What are AAC blocks?

AAC blocks are a precast, foam concrete, sustainable construction material made from aggregates of quartz sand, calcined gypsum, lime, portland cement, water and aluminium powder. After mixing and moulding, the concrete is autoclaved under heat and pressure and it thus gains its distinctive properties. AAC bricks are in high demand, owing to their high strength, load-bearing and thermal insulation properties.

Here is a quick look at the unique features of AAC blocks:

| Colour | Greyish-white |

| Lightweight | 50% lighter than red bricks |

| Fire resistance | Between two and six hours, based on the thickness |

| Energy efficiency | 25% reduction in air-conditioning costs |

| Thermal efficiency | Three times higher than clay bricks |

| Water absorption | About 10% of its weight |

| Sound insulation | 42 dB (approximately) |

| Affordable cost | Nearly one-third of the cost of regular bricks |